Instrumentation & Controls

Custom designed hermetic solutions for instrumentation,

sensors, controls, and more.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

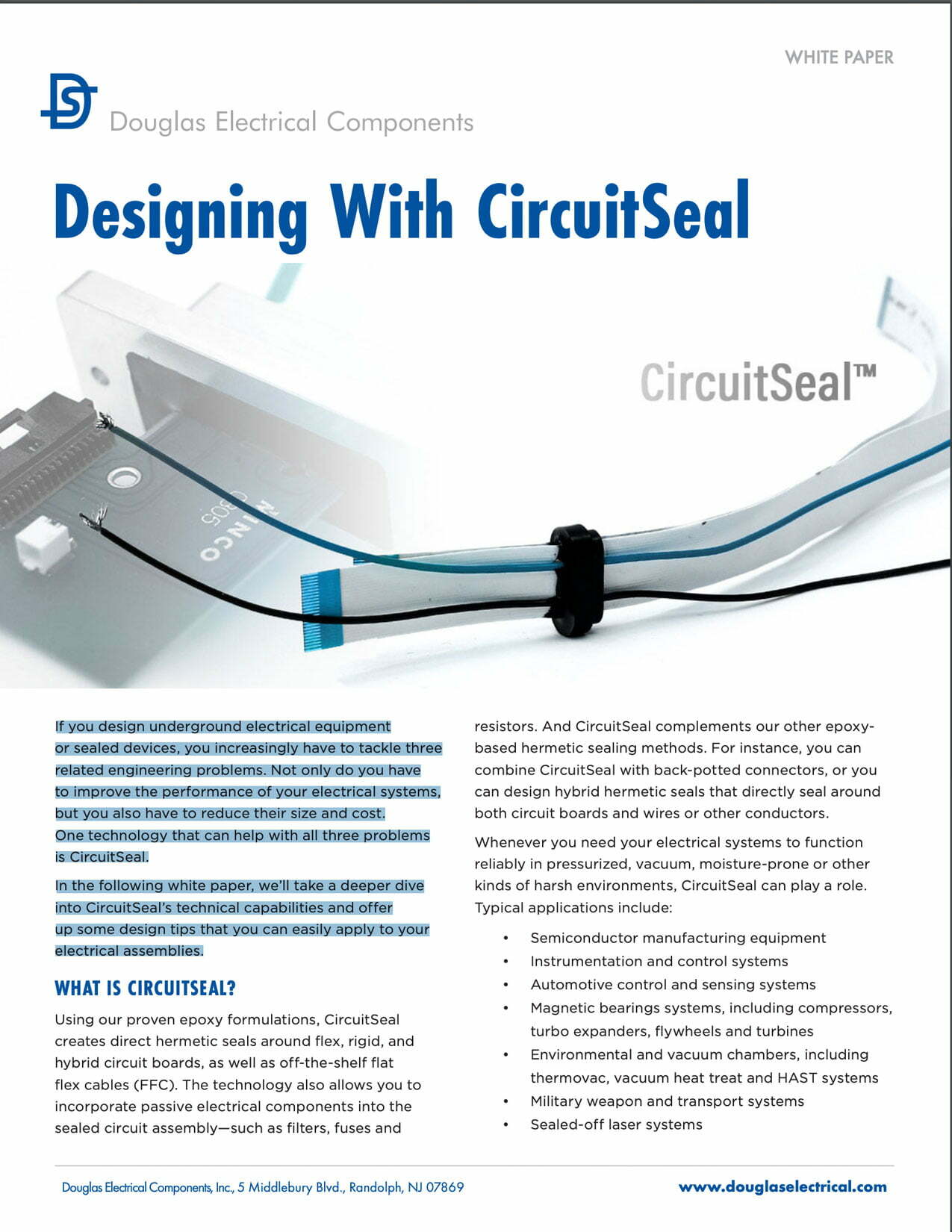

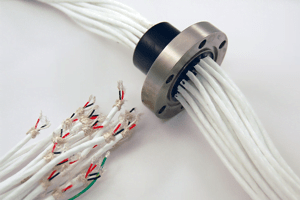

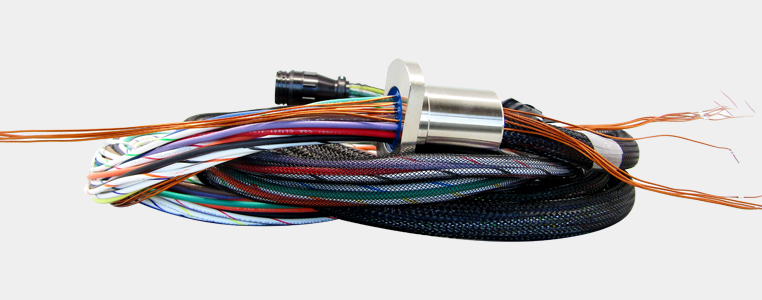

Every year, we design and deliver hundreds of thousands of instrumentation-specific sealed connectors and hermetic electrical feedthroughs for sensors, analyzers, and control systems. Feedthroughs are engineered to withstand pressures as high as 15,000 psi and voltages up to 35kV. While this industry can serve a variety of markets, Douglas Electrical Components has experience designing and manufacturing to service across them, including: Automotive, MIL/Aero, Medical, Oil/Gas/Energy, Semiconductor, UHV, HVAC/R, and Industrial.

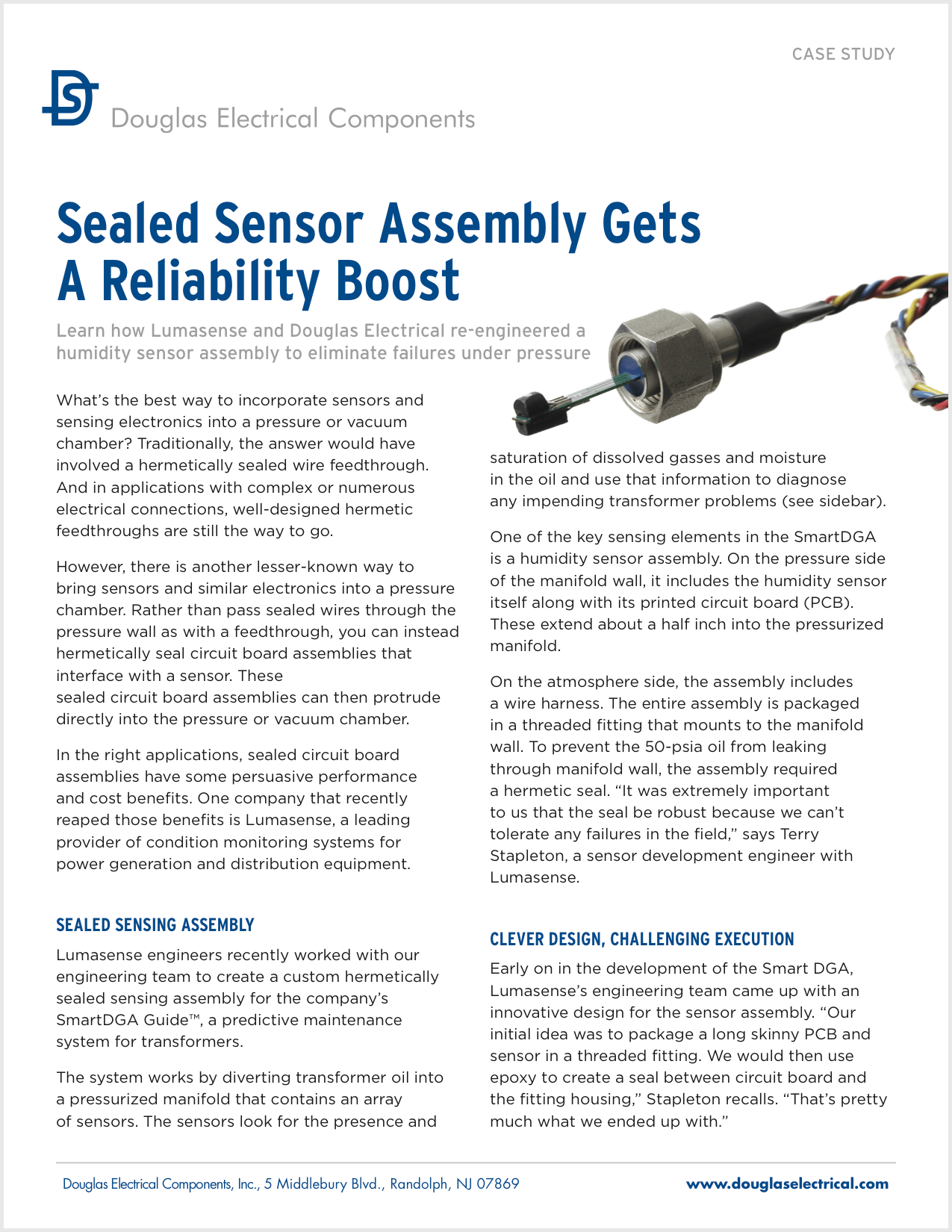

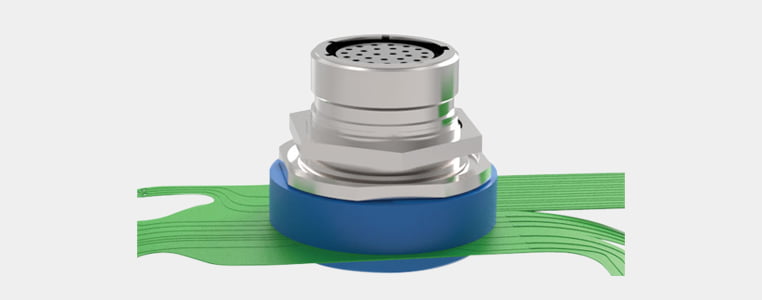

Seal the sensing element

The sensor industry can integrate hermetic seals at the sensing element through our CircuitSeal hermetic circuit assembly options transmitting both power and signal. This includes applications such as humidity and temperature sensors or mass flow controllers with the sensing element directly in contact with the liquid or gas it is measuring. Our hermetic technology offers a wide media compatibility range and sealing capability to prevent liquids and gases from reaching the housings protecting the electronics.

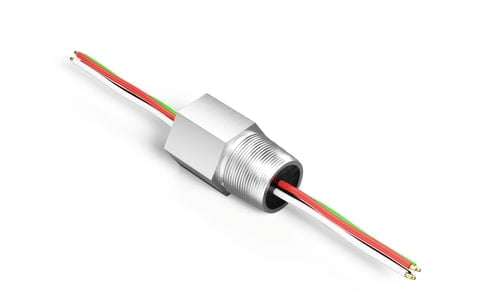

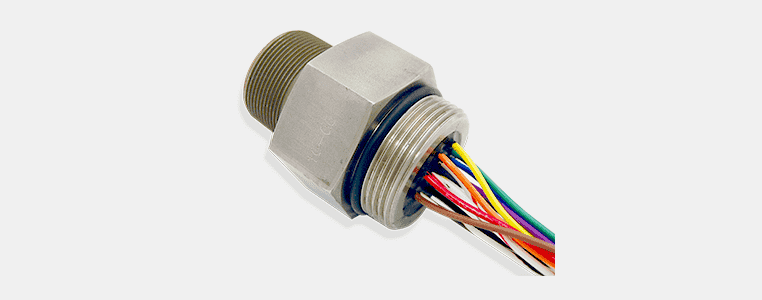

Hermetically sealing the electrical connection

Douglas Electrical Components also designs our sensor feedthroughs for the electrical connection between sensors and instrumentation and controls. Douglas offers standard wire bushings to save time on the installation of instrumentation in the field. Additionally, we customize designs for customers to hermetically seal the electronics for certification under the customer’s hazardous location file. For non-hazardous applications, electronics still require environmental protection, such as LiDAR sensors or level sensors. Douglas Electrical can design a moisture-tight electrical connection that is compatible with a variety of liquids and gases.

Customized mechanical interfaces

Customers can design a direct cast seal within their own housing or create a design that is suitable for manufacturing and the field. Sensor feedthrough housings can be constructed using a variety of materials including stainless steel, specialty alloys, and plastic materials. Our hermetic epoxy will seal to both the housing and the electrical connection to create a full hermetic assembly. Our design engineers have the experience and capability to aide your next design or upgrade to meet hazardous location approvals, with approvals for North America, Europe, and the international IECex standards. This saves you time and money when working with approval agencies to certify a sensor or transducer. Our team designs across a variety of industries and hermetically seals assemblies utilizing various housing, cable, and fiber materials.

Mechanical examples

- Radial O-rings: Our hermetic feedthroughs are integrated into housings, radial O-ring feedthroughs, and direct cast assemblies. This allows for a low profile, lightweight assembly. Additionally, achieve high pressures in a compact package.

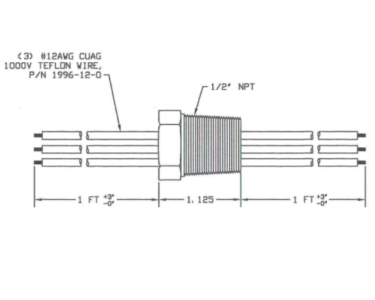

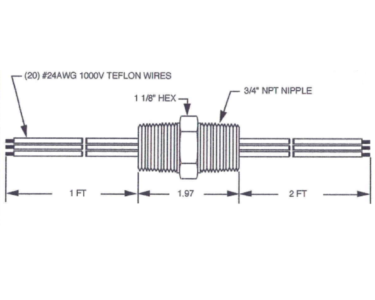

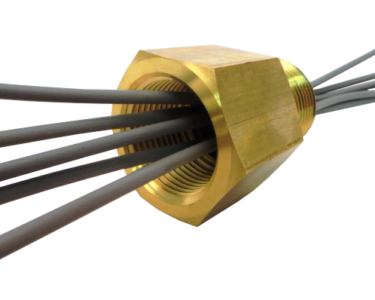

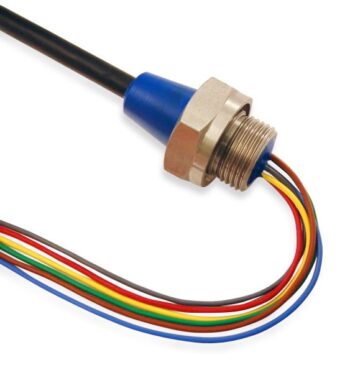

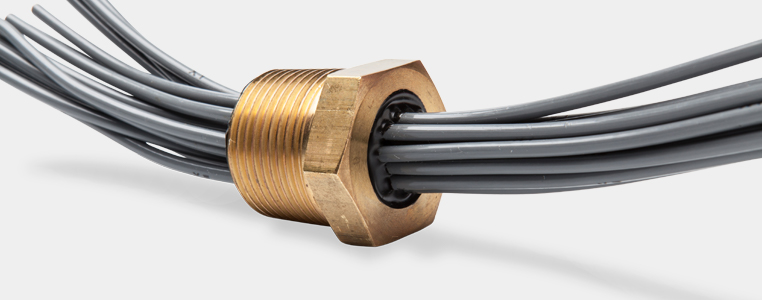

- NPT / Metric threads: For industries such as industrial, HVAC, and oil and gas, NPT threaded fittings are commonly used. These assemblies can be machined from stainless steel, brass, aluminum or specialty alloys to meet customer cost and environmental requirements. Metric threads are also available.

- Welded options: While available, we recommend laser-beam or electron-beam welding in most applications.

- Custom flanges and fittings: from vacuum face seals to ASME/ANSI flanges are available with wire, connector, or power feedthrough integration.

- Back-potted connector assemblies and circuit board seals are popular when integrating directly into a sensor assembly to increase protection while minimizing installation time.

Features

TECHNICAL ADVANTAGES

- Wide range of liquid and gas compatibility

- Design flexibility to integrate in custom housings and materials

- Hermetic cable assemblies operating in harsh, hazardous environments

- Can seal any housing material or geometry, often using customer-supplied material.

- Up to 2-inch NPT wire feedthroughs to accommodate large numbers of power leads.

- Ability to seal power, signal, coaxial and fiber optics in a single bulkhead fitting.

- Designs with or capable of hazardous locations approval

EXAMPLE APPLICATIONS

- Coaxial feedthrough seals high frequency coaxial cable operating at high pressures

- Faston* quick connect feedthrough for transmitting signals into a pressure chamber

- Miniature sealed wire harness assembly to protect sensitive aircraft GPS from moisture and condensation

- Sealed fiber optic feedthrough prevent condensation on the inside of a domed roadway monitoring camera

- Circuit board hermetic interconnect within transducer assembly

- Integral wire feedthrough or bulkhead connector for hermetically sealed control box

- Two-pin terminal seal monitor refrigerant charge in air conditioning systems

- Explosion-proof rated transducers and transmitters

*FASTON is a trademark of TE Connectivity.

COMMON SENSORS & INSTRUMENTS

- Gas chromatographs

- Pressure, temperature, position, humidity, and vibration transducers including seals creating explosion-proof rated assemblies

- Resolvers and magnetic bearing sensor assemblies

- Level and flow switches, sensors, and transducers

- Cryogenic tank level equipment and hydrogen sensing

- LiDAR and GPS assemblies

- Integral housing hermetic seals

- Medical instruments, tools, and equipment

- Test & measurement devices

- Fiber optic sensors

Featured Products

Instrumentation & Sensor Feedthroughs

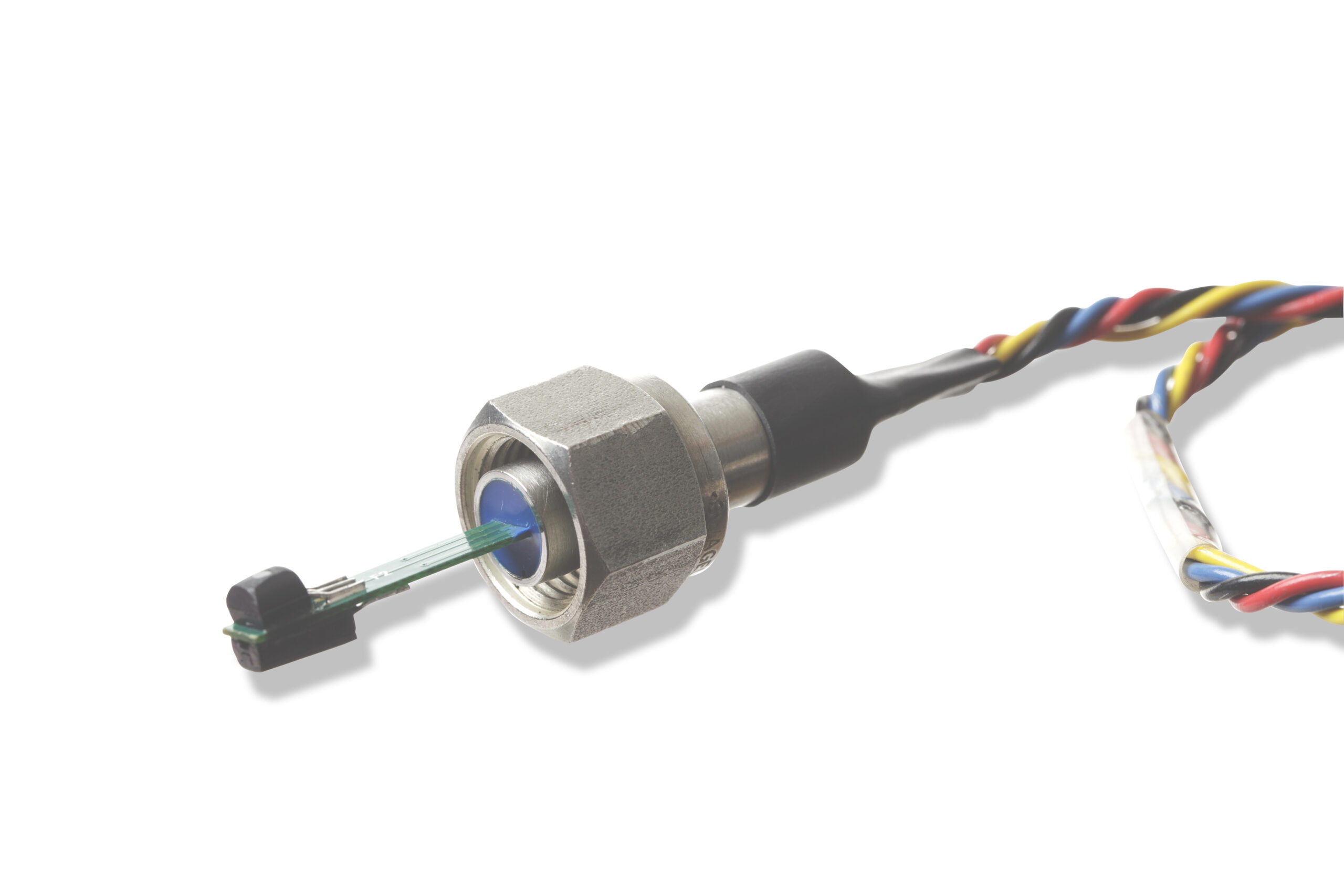

Hermetically Sealed Sensor Assembly

Hermetically sealed sensor assembly where the sensing element is exposed to the operating environment, but the housing and wire are hermetically sealed.

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

Sealed Sensor

Sealed sensing element within a process connection with integral wires.

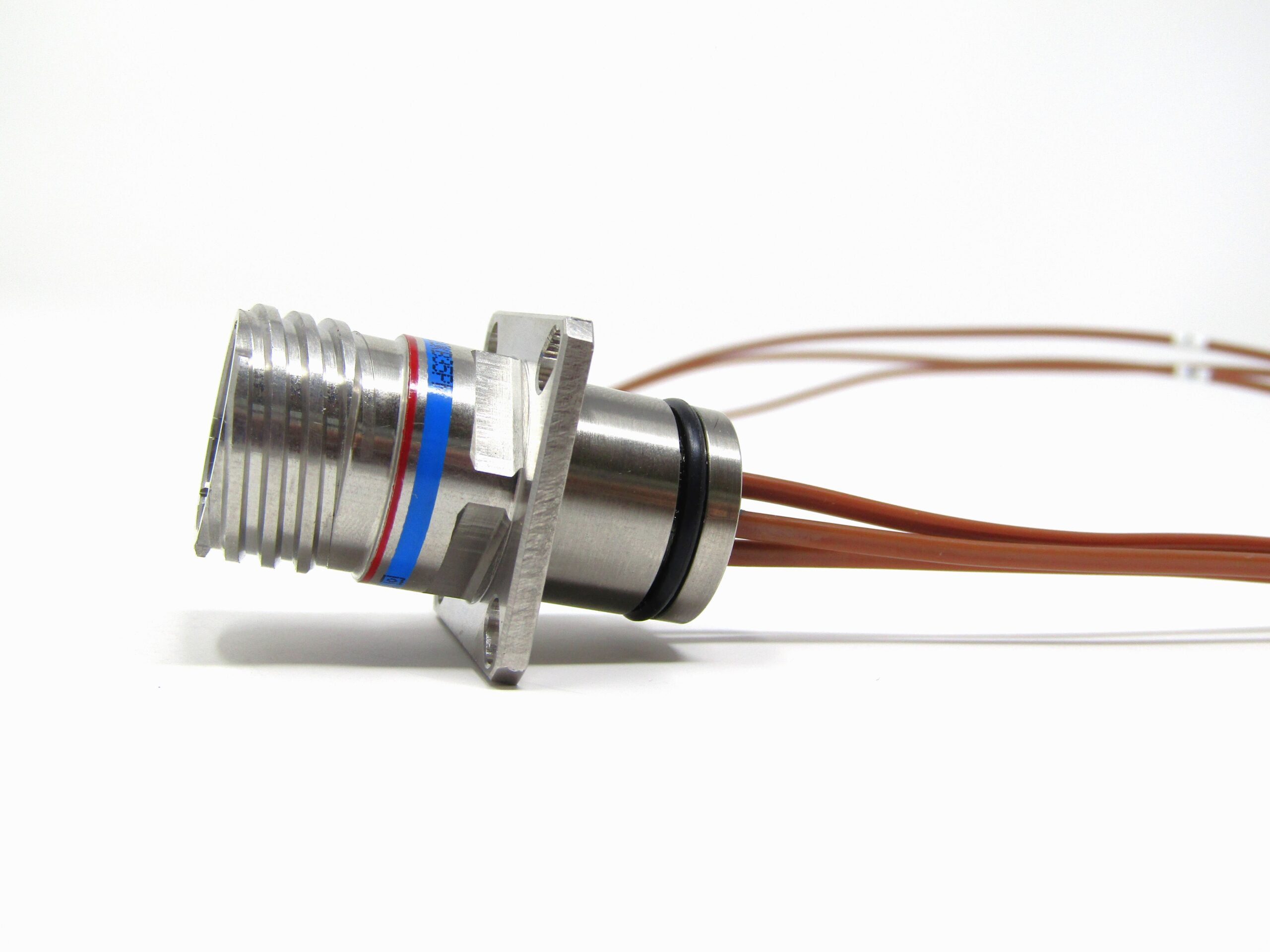

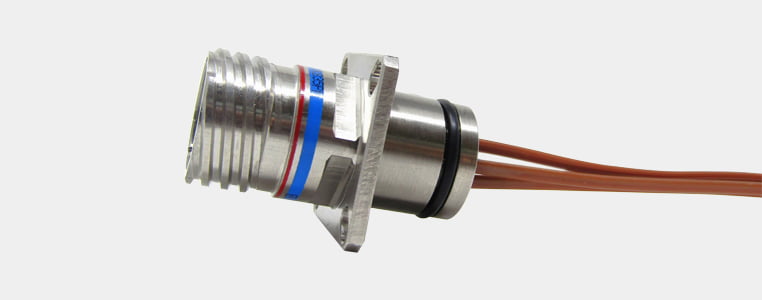

Hermetic 38999 Assembly Side View

Create a customized hermetic seal for pressure applications

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

Hermetic NPT Thermocouple feedthrough

A wire bushing style feedthrough with NPT threads and thermocouple wires

Hermetic Coax Wire Feedthrough

Hermetic coaxial feedthrough with NPT threads and coaxial wires

Fiber Optic 38999 Connector

Integral optic fiber wire assembly with backpotted 38999 connector for plug-and-play use

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

OptiSeal fiber optic hermetic connector

OptiSeal fiber optic hermetic connector; hermetically seal your fiber cables and connectors with customized bulkhead fittings.

NPT Explosion-proof Cable Assembly

Explosion-proof conduit seal with NPT threads can be designed for hazardous locations including explosion-proof environments.

RBTW Waterproof Connector with NPT and wire leads

RBTW designed for environments that are submerged in water/liquid

Backpotted jamnut connector harness

Industrial circular connector (M12) with jamnut mount and integral cable harness

Hermetically Sealed M12 Connector Assembly with integral wires and inline connector

Hermetically sealed M12 connector assembly with integral wires and inline connector

Hermetic Circular Connector

PotCon industrial circular metric connector with integral wires

Custom Ribbon Cable Feedthrough

Ribbon cable feedthroughs create a simple plug-in design for customers integrating electronics inside a housing.

CircuitSeal Connector to board

Hermetically sealed MIL-spec connector directly integrated into printed circuit board (PCB)

Flex Circuit Sealed

Hermetically sealed flex circuit assembly with custom housing

Pin to Flex assembly

CircuitSeal hermetic pin to flex assembly in custom housing

Hermetic flex circuit assembly

Hermetic flex circuit integrated with circular connector rendering

Hermetic electrical feedthrough with cable and pogo pin in flange

Hermetic electrical feedthrough with cable and pogo pin in flange

Hermetic M12 Feedthrough with NPT Bulkhead Mounting

Connectorized 6 Position M12 hermetic cable assembly designed for NPT bulkhead mounting

M12 Feedthrough Close-up

Epoxy-sealed NPT feedthrough plug with integral M12 cable assembly

Documents

Literature

Whitepapers

Material Data

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations

Related Products

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Explosion-proof wire and cable bushings

Sealed Line Bushings for Hazardous Locations

Wire & Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough

using virtually any conductor

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

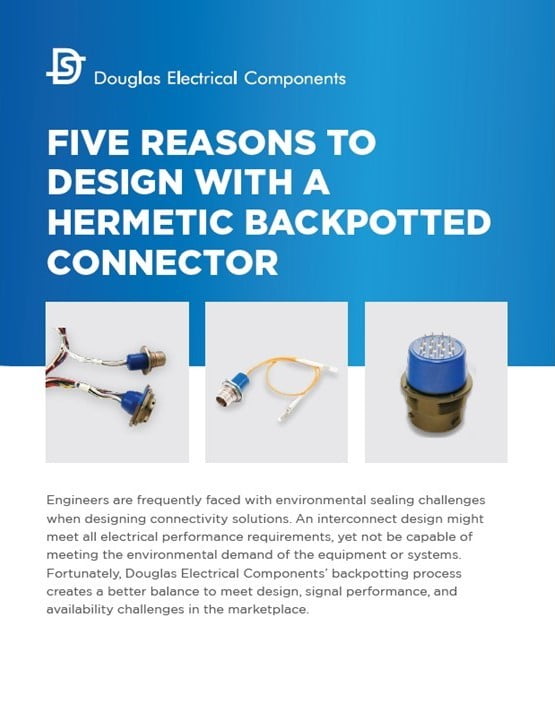

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.

Hermetic Backpotted Connector

Industry-leading made-to-order hermetic bulkhead connector assemblies

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration,

with time and troubleshooting minimized.