Electrical Power Transmission & Distribution

Protecting Power & Signal Transmission With Hermetic Electrical Feedthroughs

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

Today’s energy landscape is changing rapidly. Technological advancements, increased demand, aging infrastructure, and extreme weather events are only some of the issues currently facing the industry. Meeting these challenges requires a reliable, weather-hardened system that integrates distributed energy resources (DER) efficiently.

Ensure reliable power and signal transmission with hermetic feedthroughs. Our proprietary epoxy sealing process creates design flexibility, allowing you to work with virtually any electrical component to meet existing design challenges, or innovate to incorporate new technologies. Its chemically inert composition can be relied on for decades of use, no matter which liquid or gas is currently used within your power generation and distribution equipment.

Minimize Operational Disruptions

Hermetically sealed conductors prevent outside environmental interference with power and signal transmission to critical electronics. Expect reliable performance for decades, no matter how extreme outside weather conditions might become. Epoxy feedthroughs seamlessly integrate into the design of your substation’s equipment (transformers, switchgear, network protectors, and more), reducing costly weather-related failures.

Incorporating hermetic seals into condition monitoring equipment also aids in the prevention of eventual field failures. These feedthroughs ensure electrical signals accurately pass through a bulkhead without performance degradation, providing reliable health and other metrics of critical grid-supporting systems.

Maximize the Longevity of Your Existing Energy Infrastructure

Replacing substation assets is costly and the current grid is aging. Hermetically sealed condition monitoring devices can help you stay ahead of problem areas, reducing maintenance costs, prolonging asset life, and improving end-of-life planning.

In addition, the most cost-effective strategy in extending the lifetime of existing equipment is to monitor and replace smaller components prior to large-scale system failure. We can design turn-key solutions that can be easily installed into existing systems, ensuring optimal performance in this regard.

Applications

Hermetic feedthroughs are utilized in multiple areas of electrical generation and transmission. These include:

- Liquid-filled Transformers

- Gas-Insulated Switchgear

- Network protectors

- Waterproof and weatherproof substation electronics enclosures

- High-voltage direct current (HVDC) systems

- Generators

- Energy storage

- Nuclear power

- Renewable energy

Douglas Electrical Components has been supporting the electrical power and distribution market for over 40 years and continues to meet the demand for reliable power sources

Feedthrough Solutions

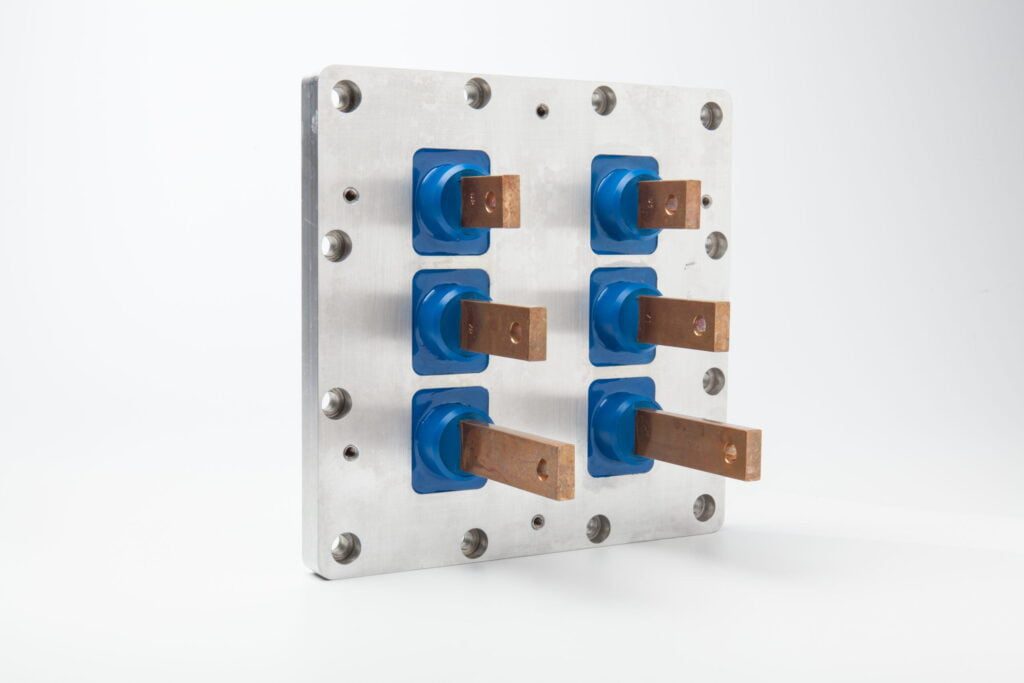

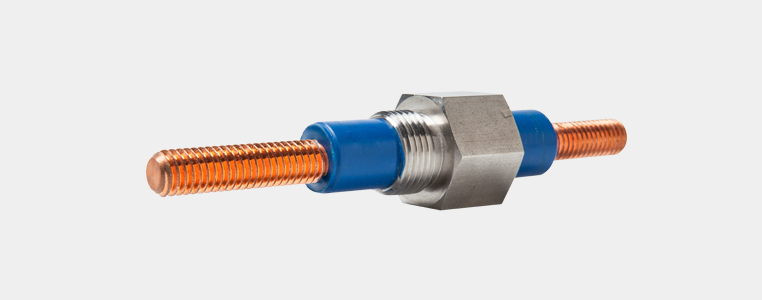

PotCon Power Feedthrough Assembly

PotCon hermetic power feedthrough assembly. Hermetically seal cables directly into the bulkhead connector assembly.

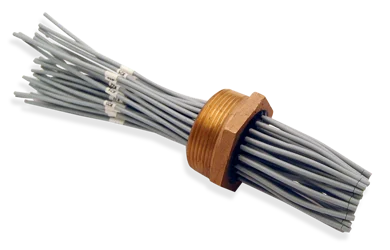

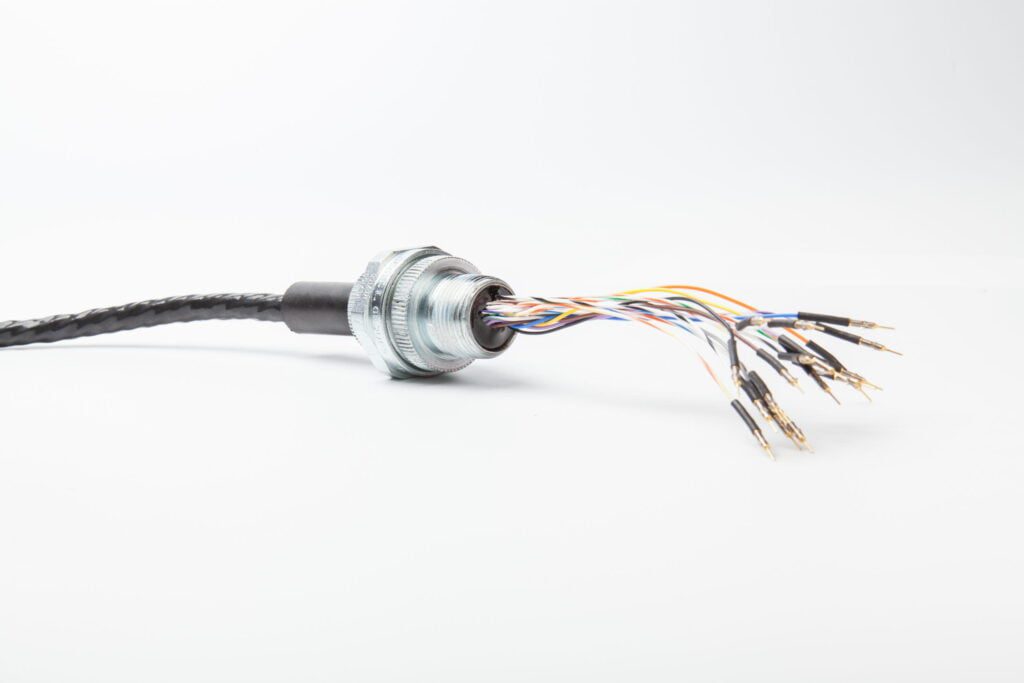

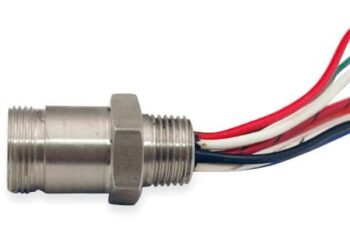

DuctorSeal Wire Feedthru

Multi-conductor hermetic wire feedthrough with NPT Threads

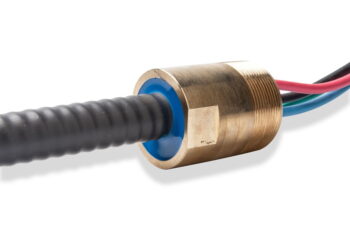

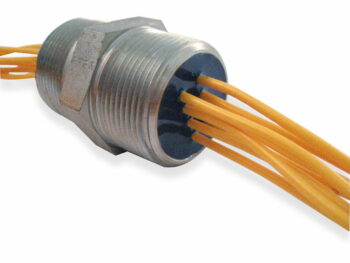

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

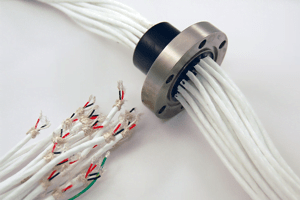

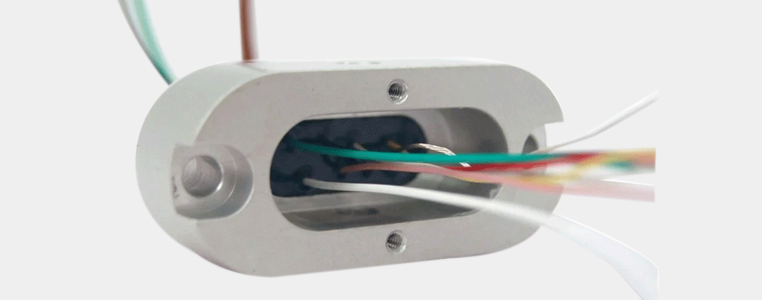

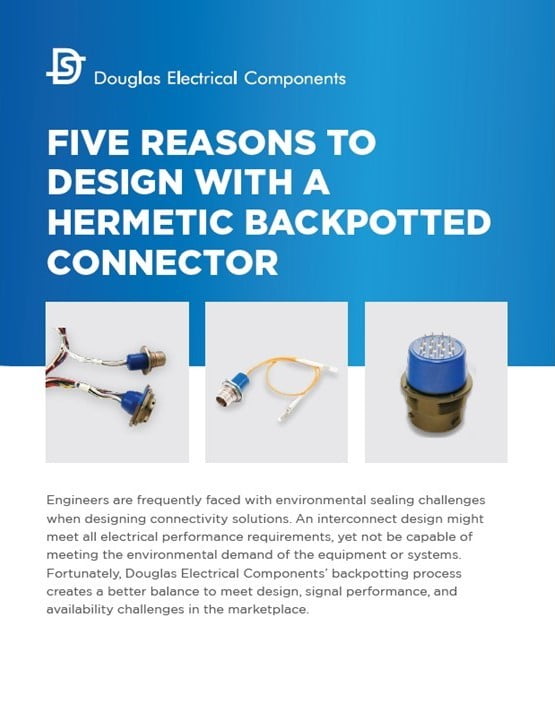

hermetic backpotted connector assembly with integral wires

hermetic backpotted connector assembly with integral wires

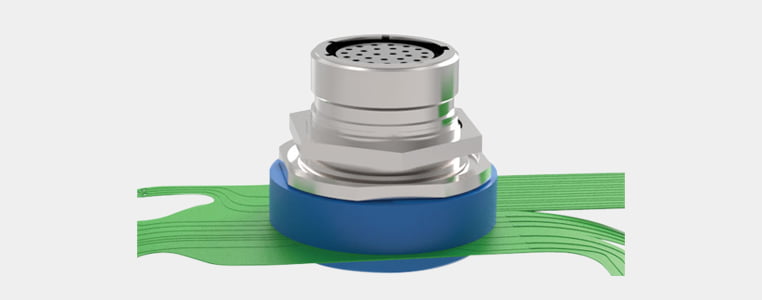

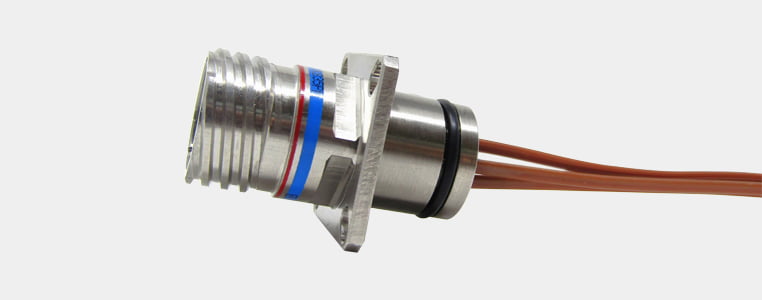

Hermetic Circular Connector

PotCon industrial circular metric connector with integral wires

Ex-proof Conduit Seal

explosion-proof conduit seal with cable to wire configuration and armor jacket

Fiber Optic Duplex Feedthru

Threaded hermetic feedthrough for optical signal transmission with integral connectors

Waterproof Push-Pull Connector Assembly

Waterproof connector assembly; seal non-hermetic connectors in cost effective packages with Douglas JacketSeal.

Hermetic Wire Power Feedthrough Connector

Hazardous area conduit seal assembly with integral connector

RBTW Waterproof Feedthru

Hermetically sealed connector--to-wire feedthrough with NPT threads for panel mounting

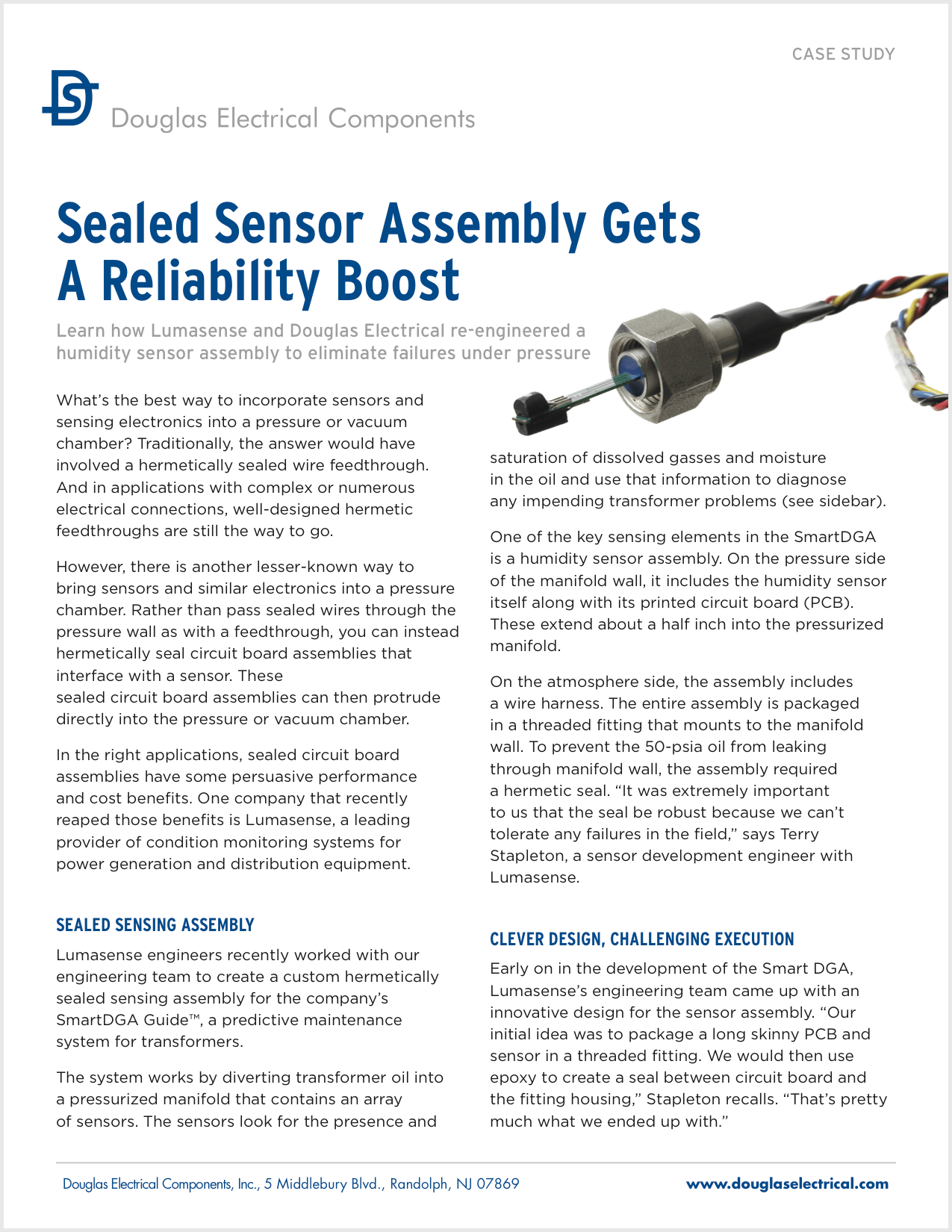

Hermetically Sealed Sensor Assembly

Hermetically sealed sensor assembly where the sensing element is exposed to the operating environment, but the housing and wire are hermetically sealed.

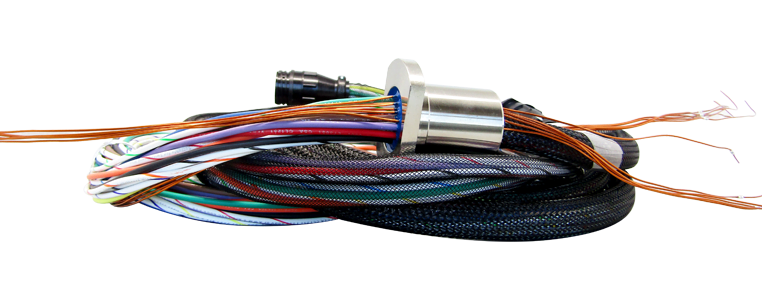

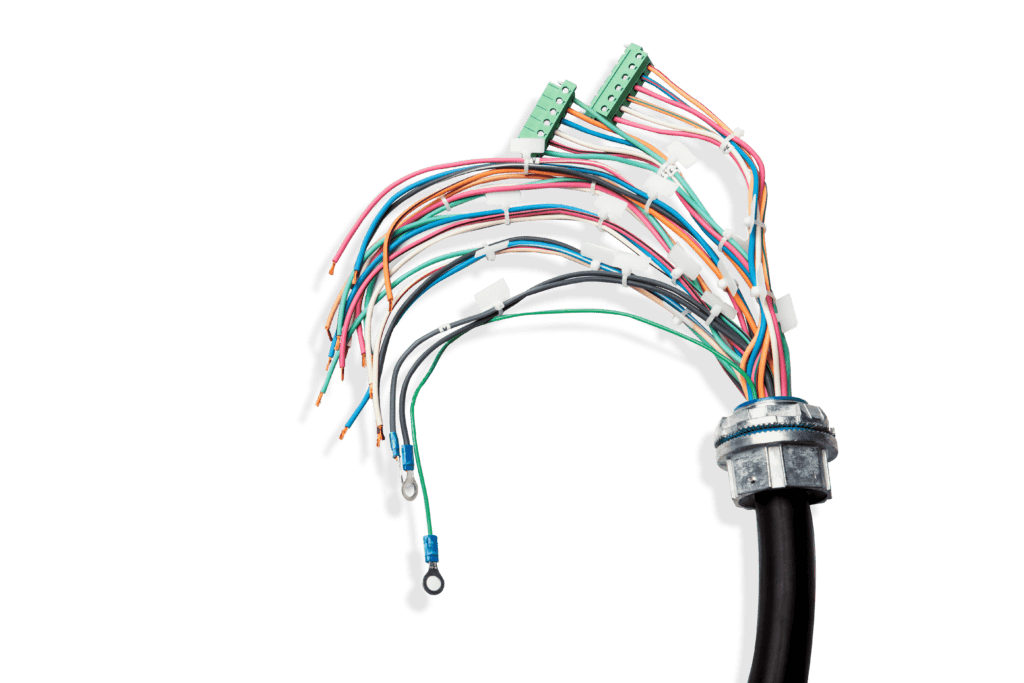

Water-tight Cable Harness Assembly

Integral circular connectors in harness meeting water-tight requirements.

Water-tight Fiber Assembly

Water-tight sealed fiber optic cable assembly

Water-proof Cable Assembly

Water-proof cable assemblies available with custom integral connection options to retrofit existing wiring or meet new requirements.

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

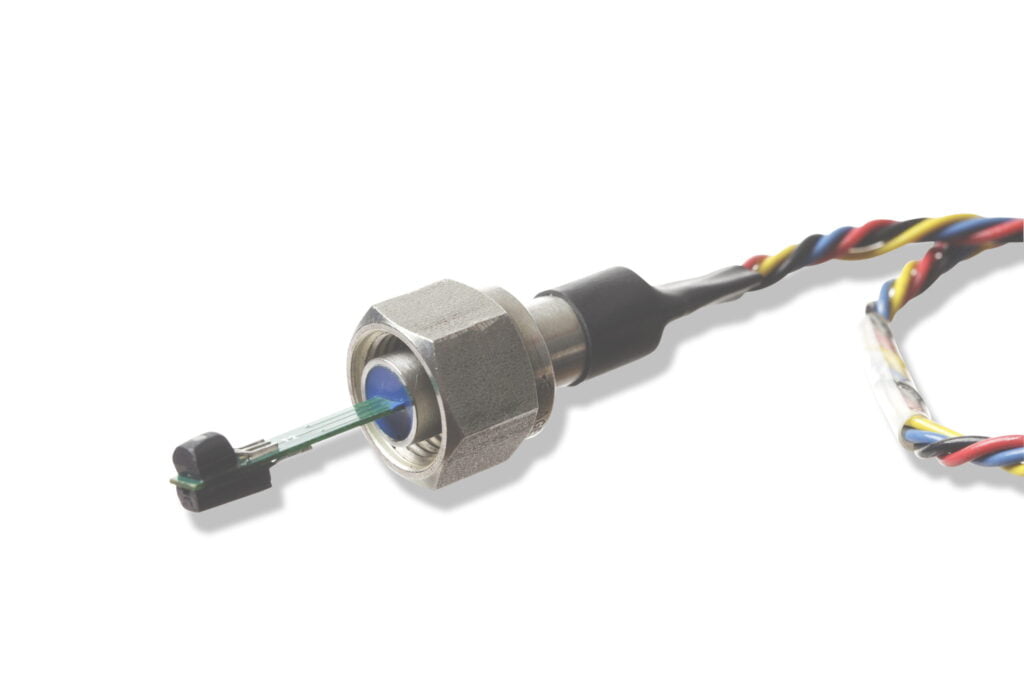

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

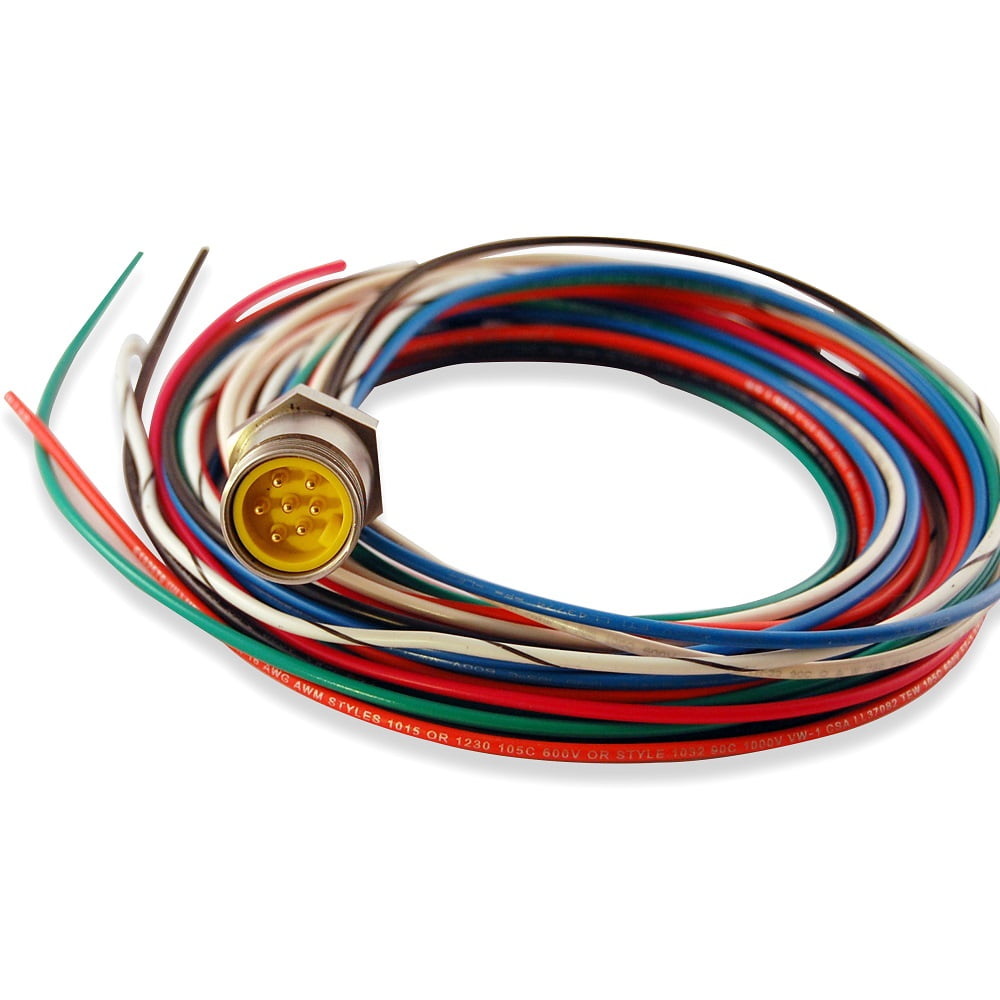

Hermetic M12 Feedthrough with NPT Bulkhead Mounting

Connectorized 6 Position M12 hermetic cable assembly designed for NPT bulkhead mounting

Related Products

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.

Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

Features

TECHNICAL ADVANTAGES

- Power solutions up to 30,000V AC

- Industrial hermetic circular connector solutions using any manufacturer or series (M8, M12, etc.) provide both waterproof connectorization and hermetic mounting

- 100% quality control testing on all shipments, including Helium leak, pressure, and electrical tests

- Robust, long-term sealing producing decades of reliable performance

- Epoxy-based hermetic seals are chemically compatible with a variety of liquids and gases.

- Bulkhead fittings are available in standard off-the-shelf configurations or custom designed and utilize materials including brass, aluminum, plated steel, and stainless steel

- Ability to use variety of cable materials, wire conductor types, AWG’s, and lengths and customize to customer specifications

- Full cable harnessing with hermetic properties for turn-key installation

- Integrate hermetic seals directly into active sensing elements.

VALUE ADDED CAPABILITIES

- Connectorized wire feedthrough assemblies and harnesses

- Custom materials and machining

- Directly integrate existing connectors, wires, cables, and termination boxes

Documents

Literature

Whitepapers

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations